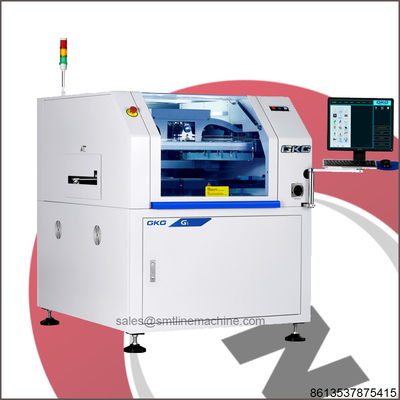

GKG G5 solder paste stencil screen printer used and new 1 year warranty

Quick Detail

G5 automatic solder paste printer is a high-precision and high-stability full-automatic visual printer. GKG company follows the development trend of SMT industry and produces a new generation of full-automatic vision printers synchronized with international leading technology. Visual processing, high-precision drive system, suspended self-propelled doctor blade, precise plate positioning processing and smart frame clamping structure, compact structure, both accuracy and high degree of flexibility, provide customers with efficient, accurate printing The required functions provide customers with outstanding cost performance.

The main technical parameters:

(1) Printing accuracy: ±0.025mm

(2) Repeat accuracy: ±0.01mm

(3) Printing cycle: <7.5s

(4) Frame size from 420×520mm to 737×737mm

(5) Printable PCB size from 50×50mm to 400×310mm

| Product Name: | Smt gkg g5 full-auto Solder Paste Printer |

| Used for: | PCB Screen Printing Stencil Machine |

| Warranty: | 1 Year |

| Shipment | by air |

| Delivery Time: | 1-2Days |

| Our Main Market | Whole of the world |

![]()

![]()

![]()

![]()

Application

Features:

1. The GKG G5 dedicated manual adjustment jacking platform is simple, reliable, low-cost, and easy to adjust manually. It can quickly adjust the height of the PIN pin top of different thickness PCB boards.

2. Image and optical system New optical system - uniform ring light and high-brightness coaxial light, with brightness function that can be infinitely adjusted, making all types of Mark points can be well recognized (including uneven Mark Point) to adapt to tin, copper, gold, spray tin, FPC and other types of different colors of PCB.

3. Scraper system slide-type scraper system to improve operating stability and prolong service life

4. Cleaning System The new wiper strip ensures full contact with the stencil, and the large vacuum suction force guarantees that the solder paste remaining in the cell hole can be eliminated. The effective automatic cleaning function is achieved: three cleaning modes of wet and dry vacuum, and the software is free to use Set the cleaning mode and cleaning paper length

5. Steady steel net fixing structure

6. Perfect 2D detection system

How does the SMT printer work?

Semi-automatic printing machine: simple operation, fast printing speed, simple structure, the disadvantage is less control of printing process parameters, printing centering accuracy is not high, solder paste release is poor, generally applicable to 0603 (inch) above components, pins PCB printing process with a pitch greater than 1.27mm.

Semi-automatic solder paste printer

Fully automatic printing machine: high printing centering accuracy, good solder paste release effect, and stable printing process, suitable for printing with fine pitch components. The disadvantage is high maintenance cost and high requirements for the operator's knowledge level.

Solder paste and patch glue are all thixotropic and sticky.

When the smt printer scraper moves forward at a certain speed and angle, it exerts a certain pressure on the solder paste, pushing the solder paste to roll before the scraper, and generating the pressure required to inject the solder paste into the mesh or the drain hole;

The sticky friction of the solder paste causes the solder paste to produce a shear at the intersection of the smc printing machine scraper and the mesh plate.

The shear force reduces the viscosity of the solder paste and facilitates smooth injection of the solder paste into the template opening or the drain hole. Scraper speed, squeegee pressure, angle between the squeegee and the stencil, and the viscosity of the solder paste all have certain restrictions, so only by properly controlling these parameters can the solder paste quality be guaranteed.